There are 4 kinds of materials for the fish feed pellet, they are:

1.1Protein Material

Cardamom om, cotton kernel, rapeseed meal, fish meal, blood bone meal.

1.2Energy material

Maize, porcelain powder,

1.3 Oil raw material

Fish oil, soybean oil, rapeseed oil.

1.4Premix Material

Some mineral, vitamin

Material Crushing→Mixing→Conveying→Pellet Extruding→Drying→Cooling→Blending

3.1 Material Crushing

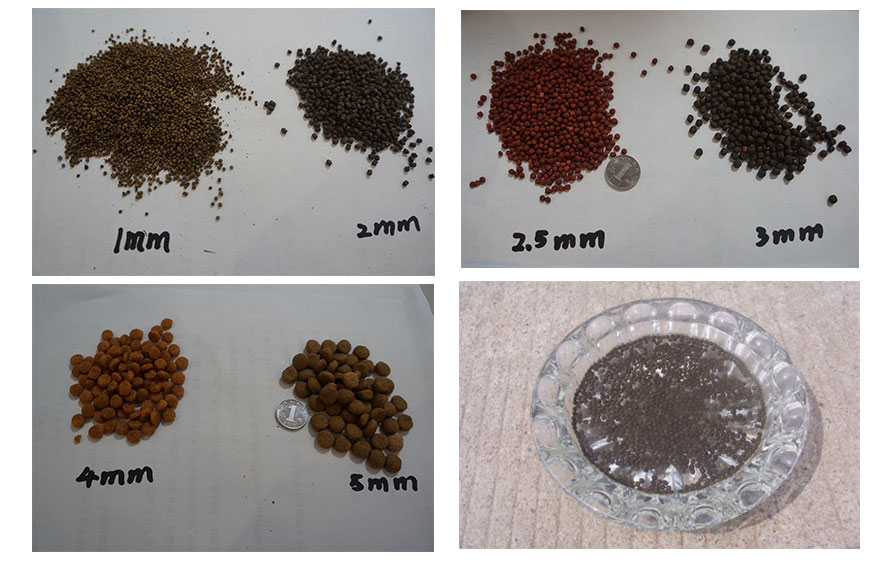

The fish feed pelletizing requires the raw material size less than 6mm, so protein or energy material needs crushing before the pelletizing process. Below is the crusher in this small fish feed pellet line.

3.2Material Mixing

In order to ensure the pellets has uniform nutrition, it needs to mix all the raw materials before the extruding process. The Screw conveyor connects crusher and mixer. This is process is very important to the finished pellet quality.

3.Pellet Extruding

3.1 Working Principle

The extruder has a pair of screws and sleeves that have the function of mixing and twisting. After the raw material enters the expansion chamber, the material is squeezed, rubbed, sheared, etc. between the screw sleeves, and the internal pressure is continuously increased, up to 4Mpa, and the temperature is continuously rising, up to 140 degrees Celsius.

During the period of 3-7s, the temperature and pressure increase sharply, and the structure of the material changes, which further gelatinizes the starch, denatures the protein, destroys the crude fiber, and kills harmful bacteria such as Salmonella. The high temperature and high-pressure materials come out from the discharge port, and the pressure is suddenly released in an instant, and the water is partially flashed.

After cooling, the material is loose and porous, and the expanded material is in the form of agglomerates, flocs or coarse chips.

.jpg)

.jpg)

.jpg)

.jpg)