Feed mill→feed mixer→wet fish feed extruder→granule dryer→automatic weighing packaging machine, the wet fish feed extruder is the important machine in the fish meal production line.

4.1 Material Grinding - Feed Hammer Grinding

The ingredients should be ground to the desired size by a feed mill. We offer three types of feed mills to meet your different requirements: A series feed hammer mills for small and medium feed extrusion plants; C series feed hammer mills for large and medium livestock and aquafeed mills B series hammer mill, also known as wide chamber concentrate hammer mill, is mainly used for fine grinding of special aquatic feed.

4.2 Material Mixing - Feed Mixer

Thoroughly mixing materials to ensure extrusion efficiency and improve feed quality. We offer two feed mixers to choose from: a two-axis high-efficiency mixer for mixing powdered, granulated, flaked and block materials, and a feed ribbon mixer for mixing powdered materials. These two blenders can be customized with an atomized spray system to more evenly add liquids such as molasses and grease.

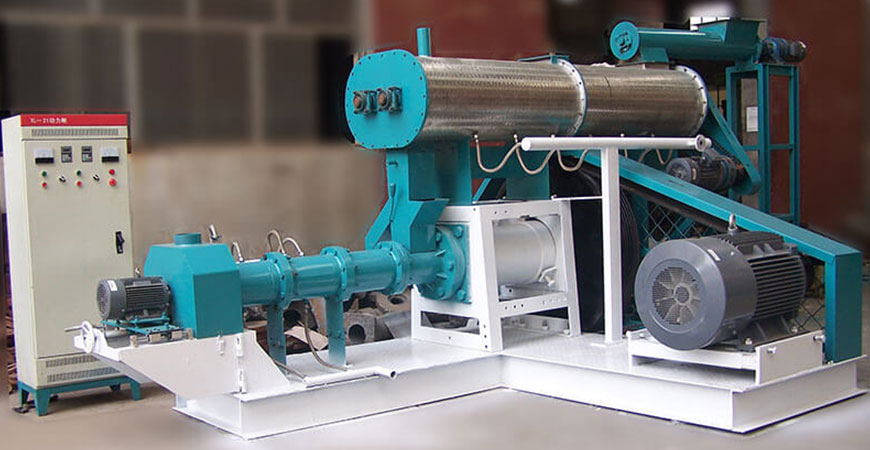

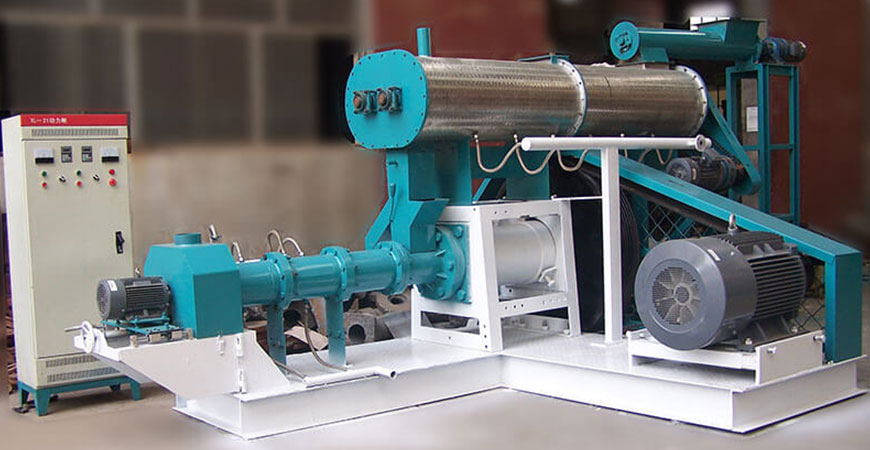

4.3 Extrusion Process - Wet Floating Feed Particle Extruder

Wet fish feeders are equipped with regulators and require a steam boiler. Wet fish feed extruders have higher capacity than dry extruders, so wet extruders are generally suitable for large feed pellet plants.

4.4 Granule drying - feed pellet dryer

Our mesh belt dryer is a continuous convection belt dryer. The pellets formed by the extruder are stacked in layers on a wire mesh or perforated belt conveyor and continuously conveyed through the drying chamber. Fish Feed Granule Dryer During this process, dry air is repeatedly passed through the product layer until the particles have an optimum moisture content before leaving the dryer. If you choose a wet fish feeder, we recommend a gas granule dryer.

4.5 Granule Packaging - Electronic Packaging Machine

In order to make the finished granules easy to store, transport and catch the customer's eyes, they should be properly packaged. With our electronic weighing and packaging machine, the finished granules can be automatically packaged, weighed, conveyed and sealed, saving manpower and time and meeting the needs of large-scale production. For this type of packaging machine, automatic hot coding, automatic seam sewing and automatic thread cutting can be optional features.