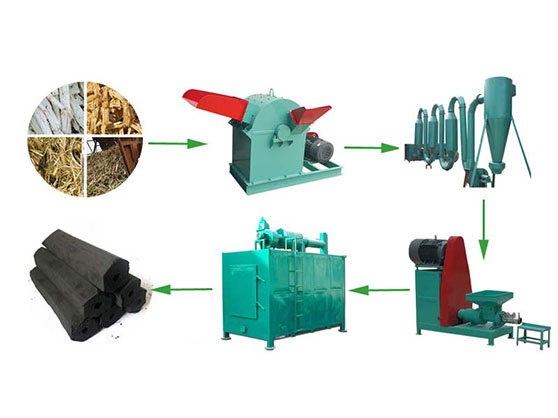

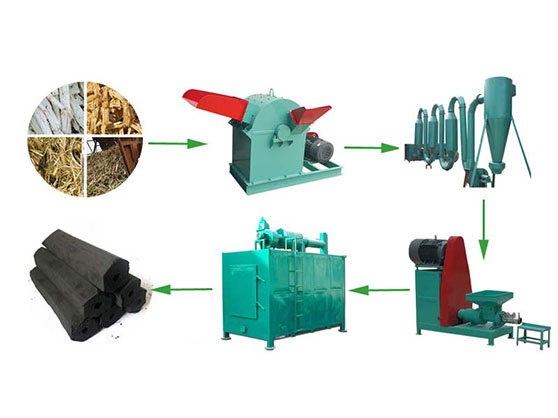

Many materials suitable to make the charcoal briquette, if the wood logs are available, they are very suitable to make the charcoal briquette directly. But since the forest resources are limited, and also this will add the cost, so more wood waste, branches, sawdust, agro waste become alternative raw materials. But these materials need some special process before they become charcoal briquette.

3.1Crushing the material into granules less than 10mm. Below are the crushing machine for wood logs, branches, straws, agro waste.

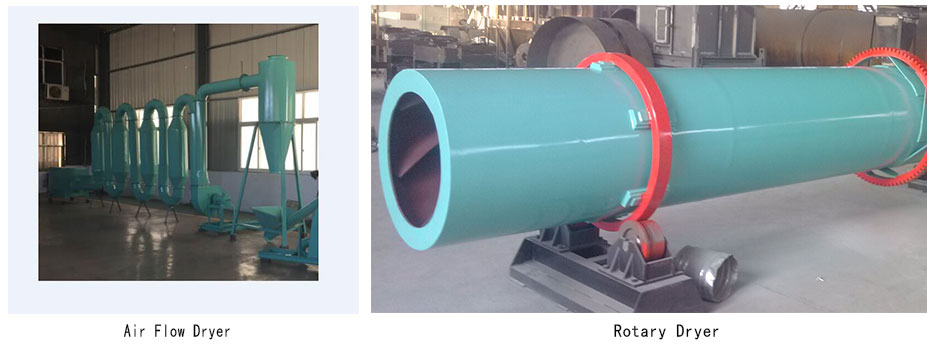

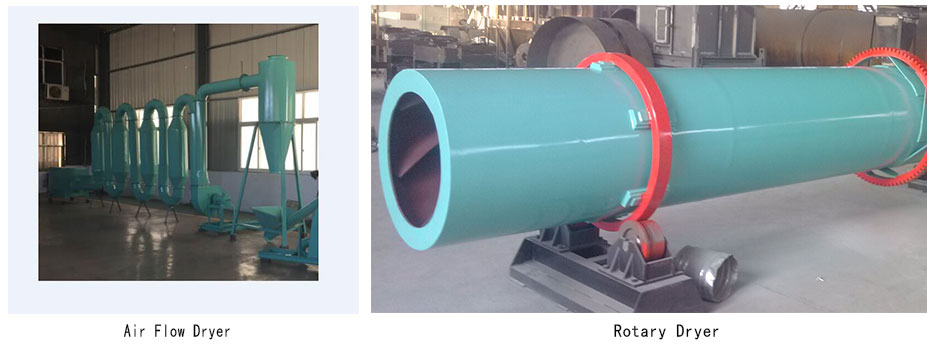

3.2 Dry the granules to reduce the moisture between 8%-12%,this process needs special attention. Below are the 2 styles dryers for different capacities.

The airflow dryer usually match small capacity production line, for large capacity line, it can't reduce too much moisture. Rotary dryer is very suitable for large capacity line, and for the material with above 30% or 40% moisture. Because its effect of removing moisture is obvious.