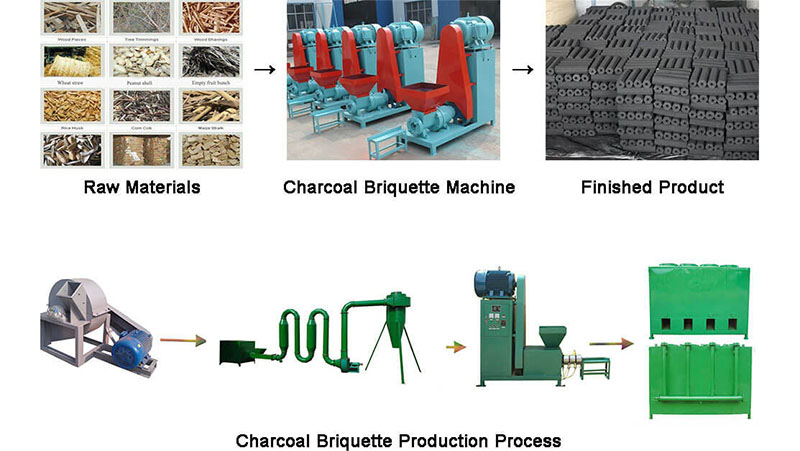

Wood shavings (sawdust), tree branches, rice husks, bamboo shavings, peanut skins, sunflower seed shells, furfural residues, wine residues, bagasse, corn cobs, coconut shells, coffee shells, and crop straws are used as raw materials. After the dryer drying into the appropriate humidity standard raw materials, then into the charcoal briquette making machine, after the high temperature and high-pressure molding into sticks (semi-finished products). Finally, through the carbonization furnace (carbonization furnace forms a variety of, generally is brick kiln) carbonization into finished mechanism charcoal.

Mechanism Charcoal And Other Charcoal Difference

1. Environmental protection. Do not cut down trees, using bamboo products waste production, turn waste into treasure. The production of ordinary charcoal to cut down trees, destroy the ecological environment.

2. High energy. The fixed carbon content is about 80% with a calorific value of 7500-8000kcal/kg, while the fixed ordinary charcoal content is low with a calorific value of 6500kcal/kg.

3. Cleanliness. Smokeless no charcoal head, combustion no spark. During the combustion, the residual ash naturally falls down and does not float up. Ash content 3% or 6% after combustion residual ashless, flammable.

4. Shape rules, reasonable structure, easy to use. Uniform length, size, hollow or solid construction, suitable for combustion and use.

5. Water content is low, within 5%. Ordinary charcoal has large water content.

6. The product contains no chemical substances, no toxic odor, no pollution, long burning time, and other advantages.

Classfication Of Machine-made Charcoal

Low-temperature Charcoal

Low-temperature charcoal is loose in texture, low in carbon content and poor in mechanical strength. It is used in industry and agriculture (such as silicon smelting plant), heating, and hotpot.

Medium-temperature Charcoal

The texture of medium-temperature charcoal is closer than that of low-temperature charcoal, and the carbon content is slightly higher than that of low-temperature charcoal. It is mainly used for barbecue, in addition to, industrial and agricultural, heating, and hot pot.

High-temperature Charcoal

High-temperature high-quality charcoal is hard and solid, heavy to handle in hand. It can sink in water, can make steel sound when struck, has high carbon content, low volatile content and ash content, no flame when burning. The burn resistance is three times that of low-temperature charcoal and two times that of medium-temperature charcoal. It is suitable for all occasions with charcoal, especially for high-grade barbecue and export.

Market Prospect

The mechanism charcoal market is broad. Catering (barbecue, hot pot, etc.) is used as charcoal for the barbecue. The mechanism charcoal density is more than three times that of ordinary charcoal, burning smokeless. Industrially, mechanical charcoal is used in the production of carbon disulfide and steel smelting. It is also used as a supplementary fuel for boilers. Its density is similar to that of coal, with a calorific value of 5,500-7,000 kcal /KG, but its ash content is significantly lower than that of coal.

.jpg)

The use of mechanism charcoal is broad, and the raw materials are relatively wide. The market sales are also dominated by large cities, and the demand is quite large. The investment threshold of mechanism charcoal is low, but the technical requirements are relatively high. In the initial stage of production, if the technical level does not meet the requirements, the loss is also possible.

Hope this article can help you to know more about mechanism charcoal with the charcoal briquette machine. If you want to build a charcoal briquette plant, please contact us.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)