1. This charcoal powder briquette machine has reasonable design, reliable manufacturing quality, simple structure, convenient operation, small size, cover small area, saving labor and electricity.

2. The designed automatic control electric heating device can adjust the dry and humidity of materials randomly, ensure the stability of discharging molding, and improve the working efficiency.

3. The main parts of this charcoal powder briquette machine are made of wear-resistant materials, which can be continuously pressed for production and durable.

4. Suitable for pressing and molding of various biomass raw materials, with low energy consumption and high production efficiency.

5. The three bearings of the old machine core are changed to four, which increases the stability and durability of the machine.

6. To replace the old oiled lubrication for oil immersion lubrication, as long as there is no shortage of oil, it can use for many years.

7. Increase the screw pitch, increase the feed amount, and thus greatly improve the output.

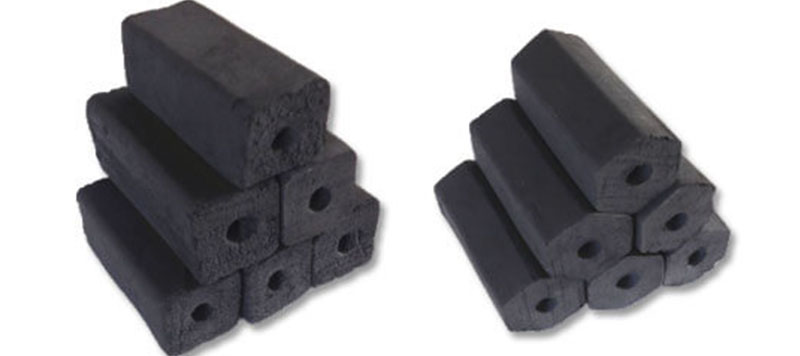

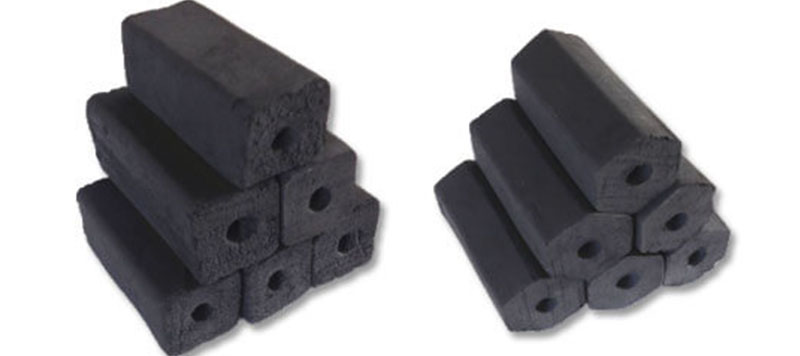

8. Improved the structure of the forming tube, reduced the friction between the machine and the raw material and increased the density of mandrel. Finished mechanism charcoal higher economic benefits.

Usage Of Mechanism Charcoal

Industrial Carbon: Industrial carbon is mainly used in the reference of industrial materials and metallurgy, carburizing of the chemical industry. A medium-sized industrial silicon plant needs tens of thousands of tonnes of carbon a year. In addition, activated carbon, carbonized silicon, crystalline silicon, thermal insulation material production and smelters, copper plants, steel mills, rubber plants, and other industries have a large number of demand for charcoal. In short, the usage of mechanism carbon in the industrial reach to hundreds of, charcoal demand is a big industry.

Charcoal used in agriculture and animal husbandry: Charcoal contributes to the production of agriculture and animal husbandry mainly by increasing soil temperature, improving soil moisture, serving as a relief agent for organic fertilizer and improving soil acidity and alkalinity. In domestic and international agriculture, the stock-raising field has a better market.

Life Field: People often use charcoal for heating, barbecue, hot pot fuel, as well as tea roasting and tobacco drying. In addition, charcoal also regulates room air temperature, humidity and eliminates harmful gases, has become a necessary product in the field of life.

Choosing a suitable charcoal briquette machine and using it properly will significantly improve the quality of the mechanism charcoal. It will soon reflect a benign effect in the production process. If you can further master the technology of making briquette, you can also greatly reduce the cost of the materials, thereby increasing profits.

Zhengzhou Fusmar specializes in the production of feed pellet machine, fish feed machine, feed hammer mill, charcoal briquette machine, and other machinery.

.jpg)